Huaxi breeding base reaps benefits from intelligent upgrade

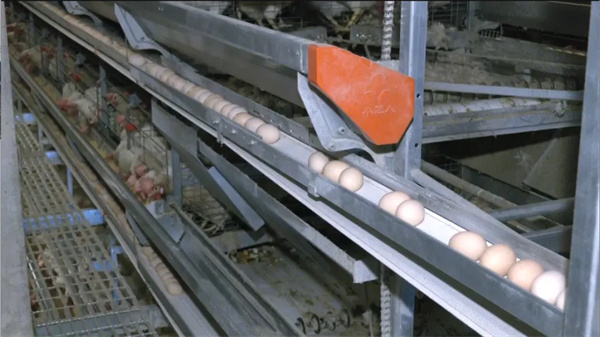

The central egg collection machine transports eggs via conveyor belts. [Photo/WeChat account of Zhizhi Guiyang]

In recent years, Guiyang City and Gui'an New Area have placed great emphasis on the development of modern facility agriculture, with Xinyuan Laying Poultry Breeding Base in Huaxi district serving as a prominent example.

By introducing intelligent breeding equipment, the entire process of laying poultry breeding has been automated, significantly enhancing production efficiency.

At the laying poultry breeding base, the original four rows and four layers of stacked laying poultry breeding equipment have been expanded to eight layers. This upgrade has increased the stock of egg-laying hens by 100,000 without increasing the land area.

The automated feeding system precisely delivers chicken feed into the troughs, and technicians use the poultry breeding digital platform to monitor the health of the flock in real time. Environmental parameters such as temperature, humidity and carbon dioxide, as well as other data, can be fully automated. The central egg collection machine transports eggs via conveyor belts for unified packaging, eliminating the need for manual collection in the chicken coops.

Currently, the base has 200,000 egg-laying hens, with two standardized chicken houses producing 6 metric tons of eggs daily and each hen house requiring only four workers to operate.

Additionally, the company has registered the "Xiaobange" brand to sell eggs, supplying Guiyang and the surrounding markets, with some eggs also being sold to the Greater Bay Area. The breeding base also helps strengthen the local village collective economy and increases villagers' incomes, with an estimated profit distribution of over 150,000 yuan ($20,670) by 2024.

"Currently, the demand for eggs exceeds supply. The next step is to expand to a scale of 500,000 chickens to meet both online and offline sales demands," said Zhang Rong, chairman of Guiyang Huaxi Xinyuan Breeding Co.

Presented by China Daily.

黔ICP备05001922号-3