Guizhou Phosphate Chemical Group lab achieves breakthroughs

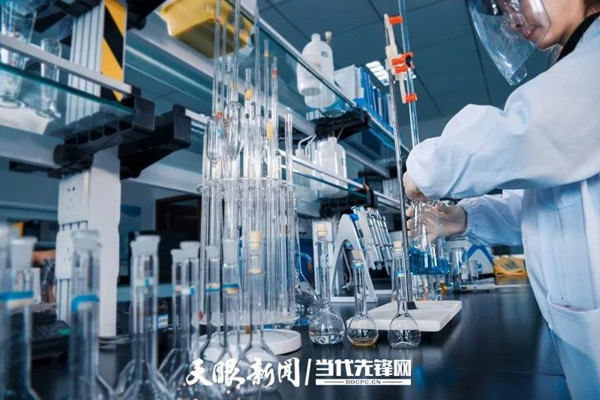

A technician works at the national lab run by the Guizhou Phosphate Chemical Group. [Photo/ddcpc website]

Since its establishment, breakthroughs achieved by the Guizhou Phosphate Chemical Group's National Key Laboratory have kept on coming.

In total, the company's National Key Laboratory for Efficient Utilization of Medium and Low-Grade Phosphate Ore and Its Associated Resources has conducted 189 research projects – achieving major breakthroughs in three key phosphate chemical technologies.

In phosphate ore beneficiation, the group's advancements – including those in reverse flotation technology – have successfully reduced the grade of phosphate ore from 30 percent to 24 percent, significantly extending China's phosphate resource lifespan.

In the recovery of associated resources, GPCG has developed efficient technologies for fluorine, iodine, and silicon – such as vacuum falling film concentration of fluorosilicic acid and feed-grade dicalcium phosphate preparations.

In particular, GPCG has pioneered the industrial recovery of fluorine from phosphate ore to produce anhydrous hydrofluoric acid, making China the first country to do so.

These technologies are said to have also led to the development of high-end chemicals like lithium hexafluorophosphate, with Guizhou's first 10,000-ton production line viewed as being critical for lithium battery electrolytes.

Additionally, converting fluorine-containing silicon dioxide byproducts into high-quality white carbon black and rust-resistant coatings is said to have opened up new avenues for silicon resource utilization.

Furthermore, GPCG has advanced the clean production of high-value wet-process phosphoric acid and developed industrial technologies for liquid polyphosphate and feed-grade urea phosphate.

It's widely viewed that these achievements have positioned China as a leader in large-scale wet-process phosphoric acid purification – bolstering the development of the new energy industry.

Presented by China Daily.

黔ICP备05001922号-3